Introduction

Contents

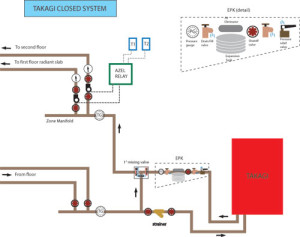

This approach utilizes a dedicated heat source for the radiant floor. The fluid in a closed system is re-circulated around and around in a completely closed loop. There is no connection whatsoever to the domestic water supply. The main advantage to this system lies in the fact that, being closed, anti-freeze instead of water can be used as the heat transfer medium. The percentage of anti-freeze (Propylene Glycol) is determined by the type of heat source (on-demand heater or tank-type) and by the guidelines listed on the anti-freeze container.

EVERY heating unit that Radiant Floor company recommends and offers is “DESIGNED & RATED FOR SPACE HEATING”! These units are not your “typical” water heaters, so don’t let the compact size fool you! All of our heating units are manufactured to an industry standard of quality and reliability.

These highly efficient heaters are built with Radiant heating in mind. We offer units that will heat both your Radiant (space heating) and domestic hot water.

Regardless of which radiant heating system you choose, be it Open, Closed, Combination unit Or heat exchanger designs, or type of fuel source you require, Propane, Natural gas, Electric or Oil,…Radiant Floor company has you covered!!!

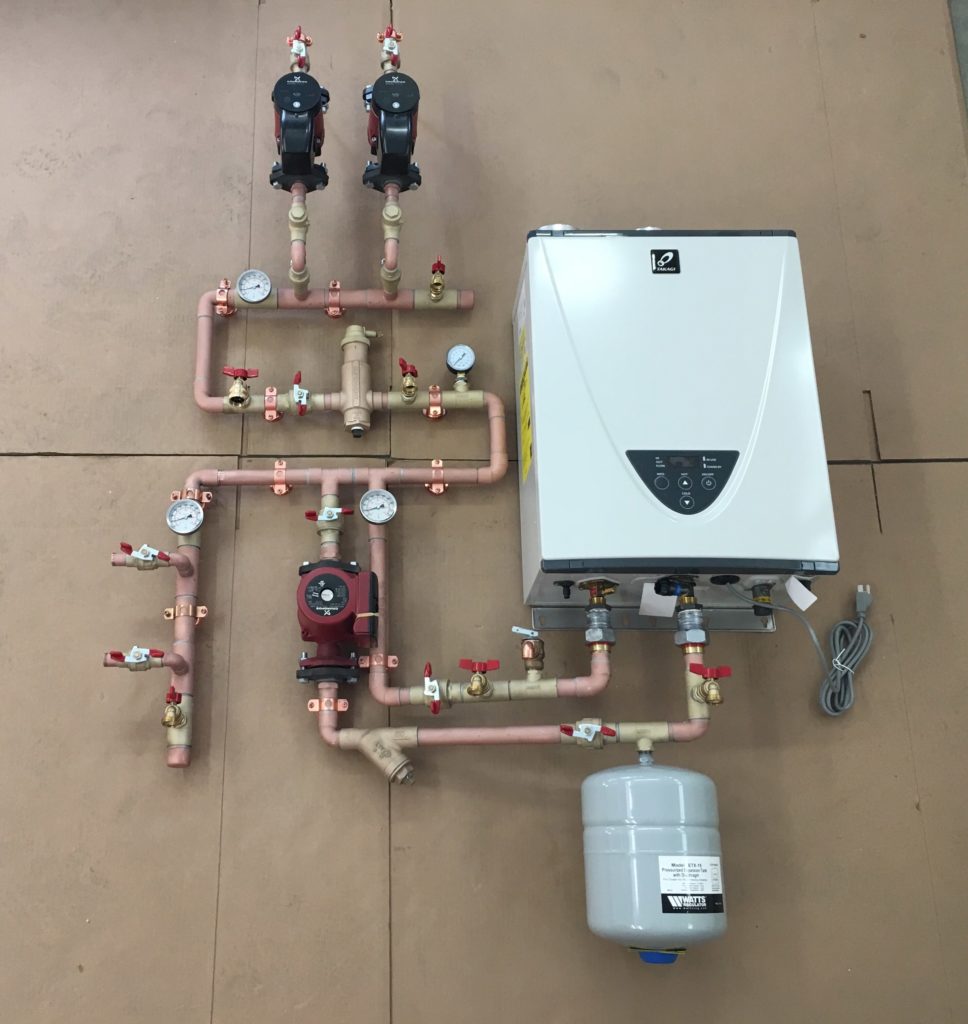

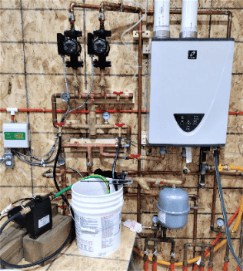

- A two zone closed system with on demand unit

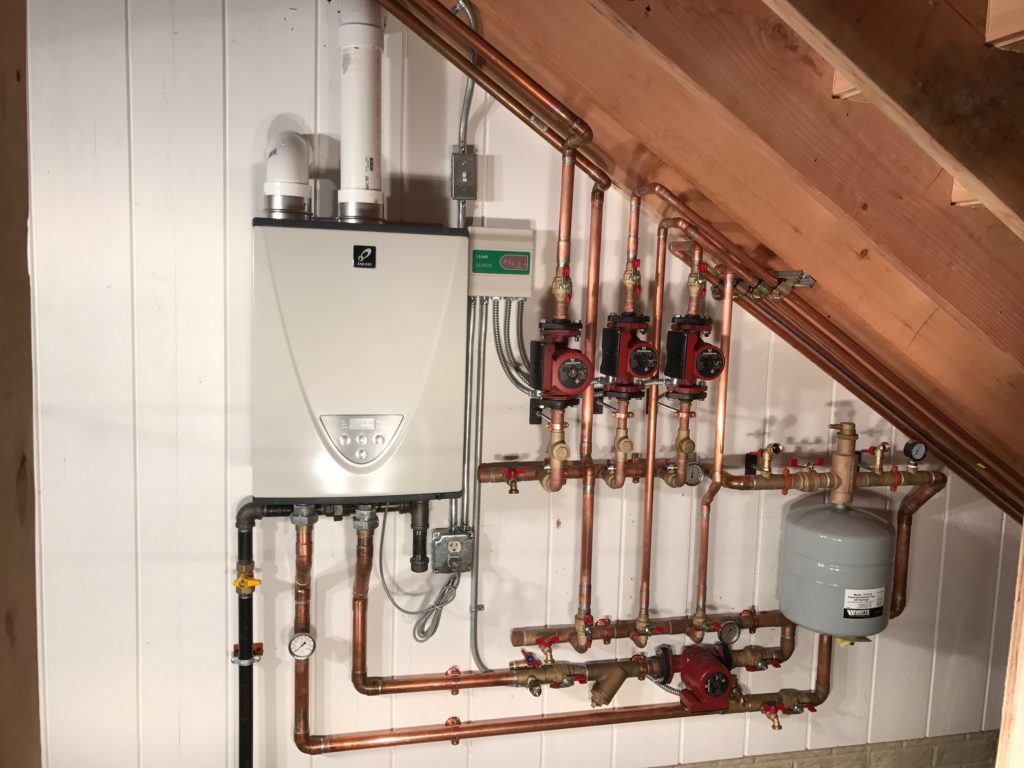

- An example of a 3 zone space saviing custom design

- 3 zone closed with electric unit

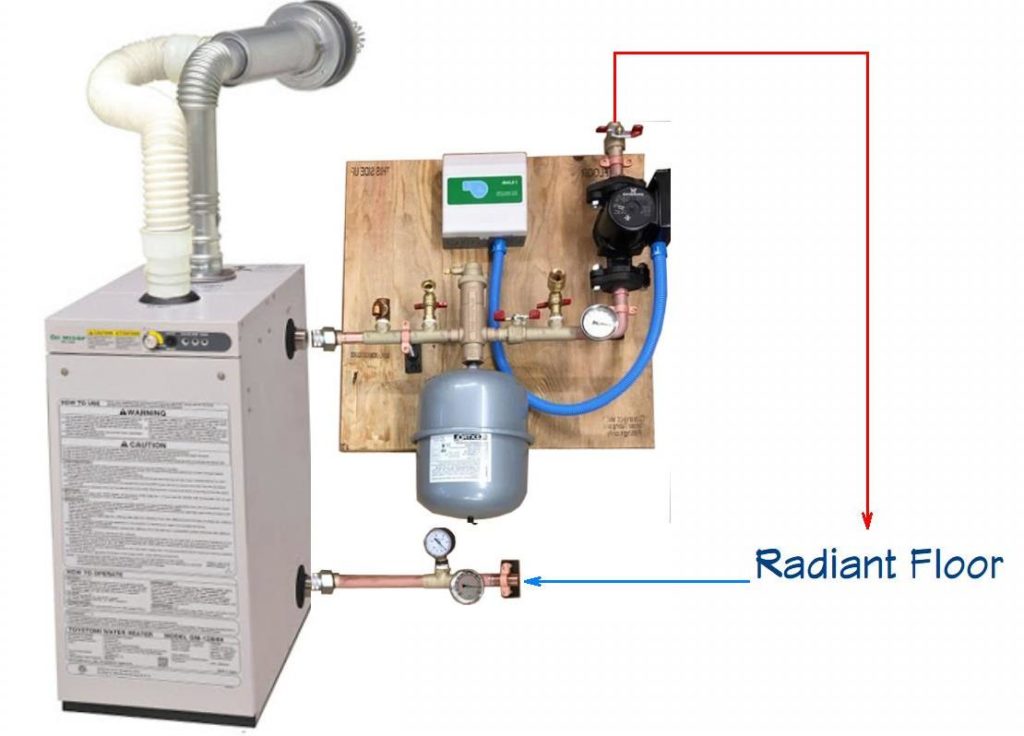

- Single zone Closed (Radiant Ready A) Using an oil fired heating unit

Closed systems are often used in second homes or primary residences in areas prone to long power outages. If freeze protection is an issue, than a closed system with anti-freeze is a good idea.

The down side is two heat sources. All water heaters waste heat energy, even when the burner is off and the unit is sitting idle between heating cycles. Granted, the unit dedicated to heating the floor only wastes heat during the winter months. But standby losses for six months out of every year can add up. The other consideration is efficiency. Two low or moderately efficient water heaters are much more costly to run than one high-efficiency unit.

Useful guidelines:

As air leaves a system, the pressure will drop. When the Radiant heating system heats up, the pressure will increase, but when it cools, it will drop in pressure….. We recommend that you maintain at least 15 psi when the system is cold. When a heated system’s pressure is near 0,… and then cools,… it will create a NEGATIVE pressure… Thus creating a VACUUM, this will suck air into the system! The Closed system expansion tank is pre-charged and should not need any pressure. If pressure is dropping below the 15 psi, it is an indication of air still trapped in your system,…. Air is the WORST thing that can happen to any (Hydronic) Radiant heating system. Follow this link, https://www.radiantcompany.com/details/fill/ for information on filling and purging your Closed Radiant heating system. We recommend Propylene Glycol (not automotive, Ethylene Glycol) antifreeze.

The cap on the air eliminator is closed when it is tightened (clockwise) and opened when the cap is backed off (counterclockwise) a few turns, so that daylight is visible through the slit in the cap,…The air eliminator cap may be removed if you wish, but is not necessary. When filling the system with liquid, the air eliminator’s cap can be either in the open or closed position. Pressure testing the system with air requires that cap to be closed so that it doesn’t release air ,…as that is it’s purpose. It is most important that the cap is opened for the duration of the system’s operation.

System Volume:

Determine how much antifreeze your system requires by adding the total amount of fluid in the tubing (2.7 gallons per 100 ft. of 7/8″ Pex …1.9 gallons per 100′ 3/4″ pex… 1.3 gallons per 100ft of 1/2″ Pex) plus the volume of water in the Heat source (water heater or boiler). Radiant Floor Company includes this information on your worksheet.

Determine what percentage of anti-freeze to water mixture is recommended by the manufacture of the heat source. Ratios can vary. Some manufacturers recommend anywhere from 20%, 30 % anti-freeze, other’s 50%. The proper mix is also influenced by the degree of low temperature you wish to protect against. Some antifreeze comes “Pre-diluted” Be sure to check before purchasing. “ALWAYS PRE-MIX YOUR ANTIFREEZE BEFORE PUMPING IT INTO YOUR SYSTEM”!

- Very nice example of a 2 zone closed system installed by the home owner.

- A beautiful closed Polaris six-zone system

- A four zone closed system using an “Electro” boiler

A heat source like an electric boiler (“Electro” boiler shown above) can be thermostatically controlled very much like a conventional tank-type water heater to send low temperature water (120-135-degrees) to the floor. However, if you are using a conventional boiler (185-degree water) for a heat source, a mixing valve is required. See below.

- Filling a single zone closed system with Electro boiler

- Example of a vertical custom design

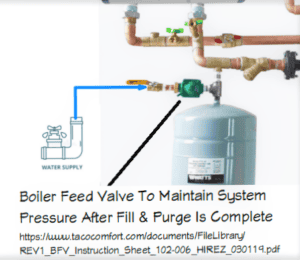

- Option for maintaining system pressure. Closed Radiant heating system equipped with an automatic fill valve. This low pressure valve will maintain a constant minimum pressure once the system is filled & purged.

“Radiant Ready” closed systems

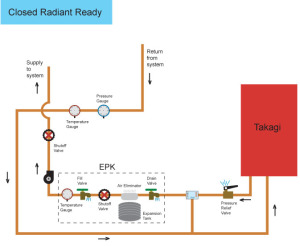

- Closed “Radiant Ready” System

- Closed “Radiant Ready” System Schematic

- A single zone system with a wall mount loop (pex) manifold

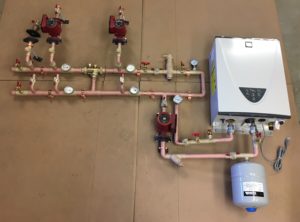

The photo above is our “Radiant Ready A/T” single zone Closed System for use with an on-demand water heater. This pre-assembled, panel system comes right out of the box just as you see it here, including pump, pre-wired controller, expansion tank, air eliminator, in-line thermometers, and various gauges and valves. The entire package is pressure tested against leaks and as few as four solder connections can tie it into your system.

This customer chose to use Unistrut channel to mount his “Closed” Radiant Ready system instead of the plywood board included in the kit, but the result is the same — a clean, compact, beautiful do-it-yourself installation. Note the addition of a mixing valve (the silver, three-way valve with the gray knob) to this system. This gives the customer a more precise control of the system’s water temperature.

A multi-zone system using an on-demand heater is configured according to the schematic below.

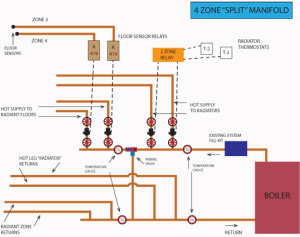

Since most conventional boilers are designed to produce super hot water (185-degrees), Radiant Floor Company builds what we call “split” manifolds for multiple zone “closed” systems that use radiant floor heat in combination with standard baseboard radiators, fan coils, cast iron radiators, or any other hydronic heating device that requires super hot temperatures.

A mixing valve is pre-installed in this type of manifold. The baseboard or cast iron radiator zones, for example, receive super hot water straight from the heat source. The much cooler radiant floor zones receive tempered water from the “mix” port of the mixing valve. The schematic below illustrates this approach.

- Four zone split manifold

- Three Zone Split

- Another example of a custom split manifold

The hotter baseboard radiator returns enter the manifold AFTER the “cold” supply pipe to the mixing valve. In this way, the cooler radiant floor returns can provide ideal tempering water. Radiant Floor Company can customize a Zone Manifold to suit any application. In this case, one leg on the left side of the manifold feeds a baseboard zone with straight 180 degree boiler water. The two legs to the right of the mixing valve supply the radiant tubing with boiler water that has been tempered by the return water down to 125 degrees.

For a single radiant zone coming off an existing, conventional boiler, this “Radiant Ready J” model includes a mixing valve to temper the 180-degree boiler water down to the much lower 120-135 degree range, ideal for in-floor systems.

The ALPHA circulator pump

Several years ago when Grundfos introduced the revolutionary “ALPHA” series of hydronic circulators to the US market, we were amazed by two things: 1) the incredible efficiency and energy saving potential of the ALPHA, and 2) by their high cost.

Nevertheless, we were excited enough to invest in several ALPHA pumps for testing purposes and we’re convinced that, if anything, the Grundfos estimates on cost savings are conservative. Now, four years later, the cost of the ALPHA series pumps has dropped dramatically and the price is now within the range of many conventional radiant circulators. As a result, we’re incorporating ALPHA circulators into our radiant system designs whenever possible so our customers can enjoy 50-75% cost savings while running their pumps.

High Volume Systems

Very large radiant systems require Primary/Secondary plumbing. If you’re interested in the fine details of this plumbing approach, you can find more information in the Heat Sources / On-demand Water Heaters / Primary/Secondary plumbing section of this website. The photo below illustrates a beautiful, real-world application of this method.

![clsdpriloop-(1)-[Converted]](https://www.radiantcompany.com/wp-content/uploads/clsdpriloop-1-Converted-300x256.jpg)

Using an Outdoor Wood Boiler With a Closed System

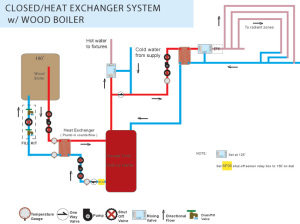

Many customers, especially in rural areas, are installing outdoor wood boilers and using them in conjunction with radiant floor heating. Normally, these boilers, via a heat exchanger, are plumbed into a storage/back-up tank that can take over the task of heating the water when the winter fatigued homeowner flies off to the Caribbean and becomes unavailable to throw wood into the boiler.

If you have an outdoor wood boiler, and for whatever reason you need to use antifreeze in the radiant floor system, the following schematic should be very helpful.

Some outdoor wood boilers are either multi-fuel systems (i.e. they can burn wood and gas or oil) or they have a built-in heat exchanger coil to supply domestic hot water. With this style of boiler the separate storage/back-up tank is not needed and the radiant floor can be run directly from the boiler.

This schematic applies to the above mentioned types of outdoor wood boilers. Just remember to bury the supply and return lines from your boiler below the frost line. Here’s why…

Normally, the wood boiler is plumbed to a heat exchanger (see drawing above). As you can see, this allows the boiler to heat a tank of potable water, which in turn can provide domestic hot water AND floor heating (in an “open” or “closed” configuration).

The water from the boiler to this heat exchanger flows 24 hours a day in a closed loop, making the heat exchanger “continuously active” (i.e. always hot). Whenever needed, the storage tank draws heat from the heat exchanger and maintains a constant tank temperature. The advantages of a continuously active heat exchanger loop are twofold:

1) the pipe from the wood boiler to the house can be buried in a shallow trench (normally about 1 ft.), saving a lot of labor and/or expensive excavation costs (obviously, with constantly circulating hot water in the supply and return lines, freezing is impossible, even in a trench well above the frost line), and

2) by keeping the water in the boiler constantly circulating, stratification is eliminated. In other words, without constant flow through the boiler, the water at the top of the water jacket gets VERY hot, and the water at the bottom stays much cooler. And since most boilers have water jackets containing several hundred gallons of water, 50% of the water in the boiler could be 185 degrees (the temperature at which the boiler damper shuts off the air supply and sends the boiler into resting mode) and the other 50% could be considerably cooler.

This means, in essence, that a boiler sized to provide X number of BTU’s of heating capacity is now providing considerably less than it’s design rating. Because when one of the heating zones calls for heat, a circulator pump comes on, water again flows through the boiler stirring the hotter and cooler water together, and suddenly 185 degree water becomes 145 degree water. This can really matter in a marginally sized system.

So, the point is, if you want to run a radiant system directly off your wood boiler, always bury your supply and return pipes below the frost line. As explained above, the water to and from your house will only be flowing when a radiant zone calls for heat. And because many outdoor wood boilers are 30 to 100 feet away from the home, a lot of water can be sitting in a cold (though admittedly insulated) trench for a long time. If that trench is above the frost line, you could have serious trouble. Multi-fuel wood boiler, or boiler with built-in heat exchanger for domestic hot water. The lines to and from the boiler must be buried below the frost line.

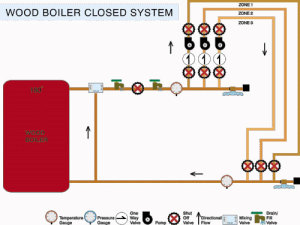

Multi-zone closed (pressurized) system using a boiler.

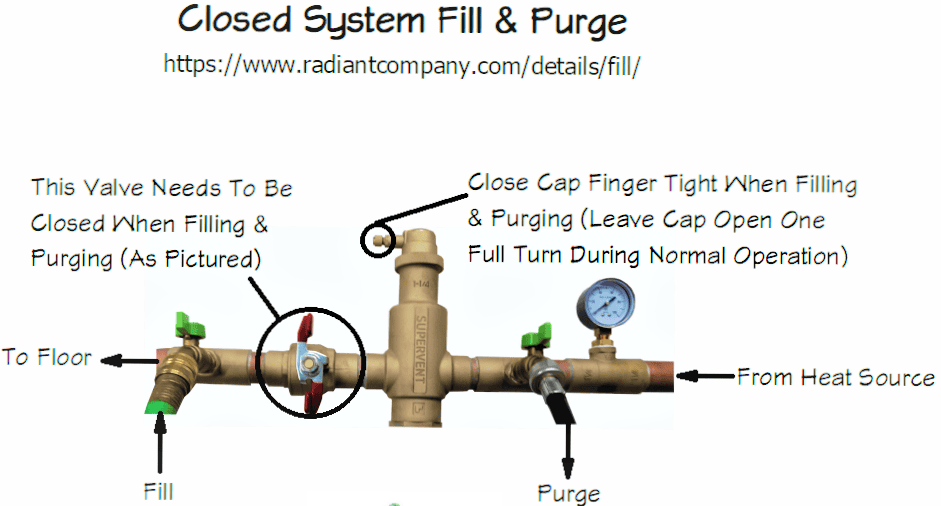

FILLING & PURGING THE CLOSED SYSTEM:

Filling and purging a Radiant heating system is a critical process! As air leaves a system the pressure will drop. When your Radiant heating system heats up, the pressure will increase, but when it cools, it will drop in pressure….. We recommend that you maintain at least 15 psi when the system is cold. When a heated system’s pressure is near 0,… and then cools,… it will create a NEGATIVE pressure… Thus creating a VACUUM, this will suck air into the system!

The fill hose needs to connect to the valve that feeds your zone pumps. Keep in mind that this valve could be left or right of the air eliminator, depending on your system’s configuration. The drain connection is the opposite valve. Be sure to CLOSE the ball valve that is between the two fill & drain valves. This forces the liquid through the zones, ensuring proper purging.

FILL FROM THE VALVE BETWEEN THE AIR ELIMINATOR AND THE ZONE PUMP,…PURGE FROM THE VALVE ON THE OPPOSITE SIDE OF THE AIR ELIMINATOR CLOSE THE BALL VALVE BETWEEN THEM.

If you are not using house pressure (from a hose etc.) then you may use a utility transfer pump, to pump the liquid into your system.

If you are you using antifreeze in your system, we recommend Propylene Glycol (not automotive Ethylene Glycol) antifreeze.

Determine how much antifreeze your system requires by adding the total amount of fluid in the tubing (2.7 gallons per 100 ft. of 7/8″ Pex) plus the volume of water in the Heat source (water heater or boiler).

Determine what percentage of anti-freeze to water mixture is recommended by the manufacture of the heat source. Ratios can vary. Some manufacturers recommend anywhere from 20%, 30 % anti-freeze, other’s 50%. The proper mix is also influenced by the degree of low temperature you wish to protect against. Some antifreeze comes “Pre-diluted” Be sure to check before purchasing.

“ALWAYS PRE-MIX YOUR ANTIFREEZE BEFORE PUMPING IT INTO YOUR SYSTEM”!

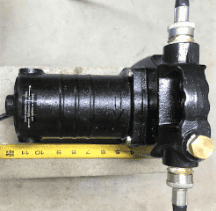

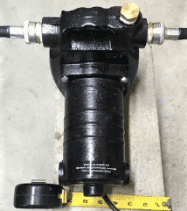

A utility transfer pump — NOT a sump pump is to be used when back flushing a unit and when filling and purging a Closed system utilizing an antifreeze mixture. We recommend a powerful utility pump like the Wayne EC-50, or the Wayne PC-4, or an equivalent pump like the Utilitech .5 HP Cast Iron Transfer Pump, all of which can generate up to 45-psi. The following link https://www.waynepumps.com/solution-center/utility-pumps-transfer/pc4 are specifications for the pump we talked about (Model # PC4).

Photos below illustrate the recommended 1/2 HP Utility transfer pump for filling and purging the closed Radiant system:

- 1/2 HP pump examples

Purging Procedure:

Be sure to fill and purge each loop within the zone separately, one at a time.

If you have three zones, for example, close the ball valves below the pumps for zones 2 and 3, and focus your water flow on Zone #1.

If Zone #1 has multiple circuits of tubing, each circuit will have a ball valve on the supply side of the loop manifold, close off all the circuits of Zone #1 except the first one and channel the water into that first circuit. When circuit #1 of Zone #1 has been purged, then close off circuit #1 and open circuit #2. Repeat this process for every circuit in every zone.

If you are not using house pressure (from a hose etc.) then you may use a utility transfer pump, to pump the liquid into your system.

We recommend Propylene Glycol (not automotive, Ethylene Glycol) antifreeze. Determine how much antifreeze your system requires by adding the total amount of fluid in the tubing (2.7 gallons per 100 ft. of 7/8″ Pex … 1.9 gallons per 100′ 3/4″ pex… 1.3 gallons per 100ft of 1/2″ Pex) plus the volume of water in the Heat source (water heater or boiler).

Determine what percentage of anti-freeze to water mixture is recommended by the manufacture of the heat source. Ratios can vary. Some manufacturers recommend anywhere from 20%, 30 % anti-freeze, other’s 50%. The proper mix is also influenced by the degree of low temperature you wish to protect against. Some antifreeze comes “Pre-diluted” Be sure to check before purchasing.

“ALWAYS PRE-MIX YOUR ANTIFREEZE BEFORE PUMPING IT INTO YOUR SYSTEM”!

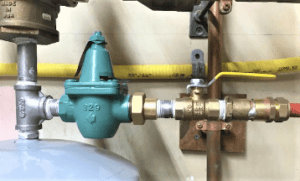

AUTOMATIC FILL VALVE:

Not every closed system uses an auto fill valve but this valve can be a good idea. Below is a typical placement examples of the “Automatic fill valve” (green valve below the expansion tank). Typically these valves are 1/2″ thread and are easily installed. These valves require a constant pressure water source and can be included with your closed system. All fittings and piping are non ferrous materials (stainless, brass and/or copper).

An Automatic fill valve supplies constant water pressure to a closed Radiant heating system at a maximum of 10 to 15 psi (see above). The Automatic fill valve, with pre-assembled shut off valve and stainless fittings are easily adaptable. Follow this link, https://www.tacocomfort.com/documents/FileLibrary/REV1_BFV_Instruction_Sheet_102-006_HIREZ_030119.pdf for auto fill valve installation & adjustment details/ instructions.

EXPANSION TANK: Your expansion tank is pre-charged and should not need any pressure. If your pressure is dropping below the 15 psi, it is an indication of air still trapped in your system,…. Air is the WORST thing that can happen to any (Hydronic) Radiant heating system. Follow this link, https://www.radiantcompany.com/details/fill/ for information on filling and purging your Closed Radiant heating system.

Expansion Tank Example

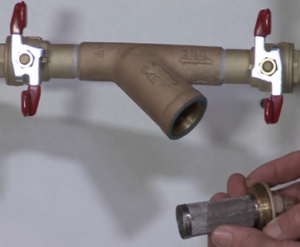

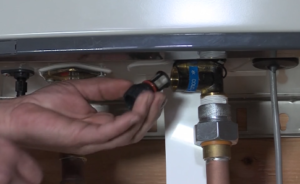

There’s not a lot maintenance for our Radiant heating systems but to clean a filter in the water heater and maintain system pressure. A system’s filter and strainer will become dirtiest when filling, purging and start up, as the impurities in the system will flow through to the strainer and filter. Flux is a solid (greasy /pasty) form when cold and liquefies when heated, particulates will loosen and move along to the strainer and filter. Follow this link, https://www.radiantcompany.com/details/fill/ and scroll down half the page for information on cleaning the filter & strainer for your Closed Radiant heating system.

NOISE:

A rumbling noise coming from the on demand water heater is (most likely) liquid boiling as it passes through the heat ex-changer in the water heater. This is due to liquid traveling too slowly through the unit. This reduced flow is caused by either a constriction or obstruction in the system’s plumbing. A dirty filter and/or strainer, Improper piping, sticky, obstructed or clogged check valve or mixing valve, mineral build up, (a result of hard water), improper pump speed setting, too much antifreeze-if applicable (closed system) or the water heater temperature set too high. The culmination of any,…(or) all of these can lead to a noisy heating unit!

The last time that you take the filter out of the water heater to clean it, and it’s clean,….. you may remove it, as it is designed to simply “Snap off” from the black cap, this will reduce head pressure and minimize any chance of the a-fore mentioned. The inline strainer is to stay in the system.